What is the difference between a copper flat roof installed by professional experienced coppersmiths and the average roofing contractor?

It's all in the details. For example, the soldering of copper flat roof panel seams. This is the most critical part of the job and the one area that most roofers fall short. I spend a good portion of my year replacing failing copper roofs that are in many cases less than 5 years old. These are a few examples.

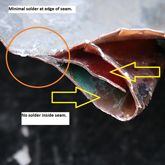

The following pictures show typical cracks and broken solder seams on flat copper roofing that I have found in the Greater Cleveland / Northeast Ohio area.

These breaks all have one thing in common. Poor soldering of the joint.

A superficial layer of solder was applied to the top and edge of the copper seam with very little penetration of the copper layers. Resulting in a very weak seam that will fail and leak.

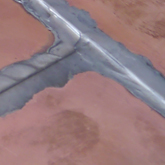

The properly soldered copper flat roof seam.

The right tools, attention to details such as soldering iron temperature, type of flux and solder, and preparation of the seam will result in a solid strong joint that will last a lifetime.

What to watch for | Signs of poorly soldered copper roofing

Seams that look like the solder was poured or caulked onto the joint. Almost as if there were a puddle of solder covering the seam.

A properly soldered copper flat roof seam.

A well soldered roof seam will have a thin coating of solder on the top of the seam while most of the solder has been pulled into the copper sheet metal folds.

The example below is from a recent copper bay roof replacement in Shaker Heights, Ohio.

New slate roofing and slate roof repair in Greater Cleveland and Northeast Ohio.

We install and repair slate roofs with time tested methods and materials. Using the best quality slate from New England quarries, copper nails and flashings, and proper underlayments, we can install a slate roof to last for generations.

New slate roof installation in Rocky River, Ohio.

After a major hailstorm damaged the existing roof, we installed a new Vermont semi weathering mixed color (greens and purples) slate roof with new copper roof ornaments and flashings.

New slate roof : Cleveland Heights, Ohio.

This beautiful house in a Cleveland Heights historical district had originally been roofed with a poor quality "pennsylvania gray" thin slate that had worn out. Many of the slate shingles were broken or missing, and others had deteriorated into paper thin layers of flakey rock. The existing slate roofing, steel flashings, and galvanized gutters were removed. Rotted roof sheathing and rafters were repaired or replaced. Premium ice guard and underlayments were installed. A new high quality, smooth textured, uniform black "North Country" slate roof was installed with copper nails and copper flashings. Heavy duty copper "euro style" rain gutters and downspouts were installed to control the rain flow.

I've been in the roofing business since I was a kid. My dad started in the fifties installing asphalt shingles, wood shingles and asphalt roll roofing products. My older brothers joined him at a local roofing company as they graduated high school. From my early teens I spent weekends and summers helping out on side jobs, cleaning the job site and carrying materials. In the mid seventies my dad started his own business with my brothers and I joined them when I graduated high school.

In 1988, the year my first daughter was born ( she is now a freshman at Washington and Jefferson College in Washington, PA.,) I started my own business to concentrate on the more challenging and high end roofing work. Slate roofing, tile roofing, copper flashing and downspouts, and ornamental sheet metal work.

From my early years, without realizing it, I had become a historical preservationist. Each time I worked on replacing an old roof, I looked at the details to see how it was originally installed. If the original roofing had lasted for many years, I figured that the workmanship had been done the best way possible and that I should try to replicate it as faithfully as possible.

Years of experience, along with researching old technical manuals as well as new, have helped me to learn how to restore and preserve historical roof systems, and sometimes to improve on the original.

Dennis M. Crookshanks

Page 2 of 3