What is the difference between a copper flat roof installed by professional experienced coppersmiths and the average roofing contractor?

It's all in the details. For example, the soldering of copper flat roof panel seams. This is the most critical part of the job and the one area that most roofers fall short. I spend a good portion of my year replacing failing copper roofs that are in many cases less than 5 years old. These are a few examples.

The following pictures show typical cracks and broken solder seams on flat copper roofing that I have found in the Greater Cleveland / Northeast Ohio area.

These breaks all have one thing in common. Poor soldering of the joint.

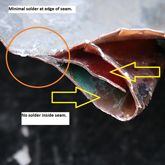

A superficial layer of solder was applied to the top and edge of the copper seam with very little penetration of the copper layers. Resulting in a very weak seam that will fail and leak.

The properly soldered copper flat roof seam.

The right tools, attention to details such as soldering iron temperature, type of flux and solder, and preparation of the seam will result in a solid strong joint that will last a lifetime.

What to watch for | Signs of poorly soldered copper roofing

Seams that look like the solder was poured or caulked onto the joint. Almost as if there were a puddle of solder covering the seam.

A properly soldered copper flat roof seam.

A well soldered roof seam will have a thin coating of solder on the top of the seam while most of the solder has been pulled into the copper sheet metal folds.

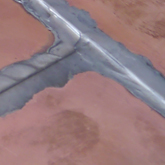

The example below is from a recent copper bay roof replacement in Shaker Heights, Ohio.