Repair of a leaking copper roof panel on a Frank Lloyd Wright "Usonian" design house with Bermuda-style roofing.

Copper Roof Repair in Cleveland & Northeast Ohio

At DM Crookshanks Construction, we offer expert copper roof repair and installation services for historic homes, churches, and significant buildings throughout Greater Cleveland and Northeast Ohio. With over 35 years of craftsmanship, our team understands the unique demands of copper roofing and delivers solutions built to last for generations.

A copper roof is beautiful, sustainable, and nearly maintenance-free—but when repairs are needed, timely service is essential. Our copper roof repair specialists handle seam reinforcement, panel replacement, flashing repair, and full restoration of historic copper details. By addressing issues early, we protect your home from leaks, extend the lifespan of your roof, and preserve its architectural beauty.

We also install standing seam copper panels, batten-seamed systems, and decorative shingles using traditional folding and soldering techniques for watertight, long-lasting results.

📞 Call 440-285-3200 today for trusted copper roof repair in Cleveland and Northeast Ohio.Can a copper roof be repaired?

Damaged or leaking copper roofs can often be repaired, but whether to repair or replace will depend on several factors. These include the extent and severity of the damage, the location of the affected area, and the age of the roof. In cases of a leaking copper roof, the success of repairs largely depends on the original installation techniques, roof design, and the skill of the original installer.

Factors to Consider When Repairing or Replacing a Copper Roof

-

Age of the Copper Roof

As copper ages, it develops a layer of copper oxide known as copper patina. This patina begins as a thin coating with a dark bronze or olive hue and gradually thickens over time. Typically, it turns light green after about 15 to 20 years, depending on the local climate. The thickness of the patina varies based on the roof's design; areas with less exposure to erosion will have a thicker patina, while those with more exposure will have a thinner layer. For effective repairs, this patina must be removed mechanically to expose clean, bright copper of sufficient thickness before soldering a repair patch.

-

Severity of Roof Damage

Small damaged areas can often be repaired quickly and efficiently. However, if a large portion of the roof is damaged, it's essential to evaluate whether it's financially sensible to repair it. In some cases, the cost of materials for repairing the existing copper may be higher than the labor costs associated with installing new copper roofing.

-

Location of Damage

Damage located along standing seams and horizontal seams is particularly challenging to repair. The additional layers of folded or lapped metal make it difficult to open and clean the metal joints sufficiently for proper soldering or panel replacement.

-

Roof Design

Sometimes, the roof area may be improperly pitched or too flat for a standing seam roof. Additionally, seams and panels may be installed incorrectly, such as seams running horizontally on a barrel-style roof.

Examples of Repairable and Unrepairable Copper Roofing

-

Repairable copper roof.

Falling slate shingles damaged this 100-year-old copper flat seam roof. The copper has a thick layer of copper patina, which has protected the metal from wear and tear. With careful cleaning and preparation, a new copper metal patch can be soldered over the damaged areas for a permanent repair.

-

A poorly soldered, leaking roof seam that is new enough to warrant repair.

Copper roof repair is in progress. The seam has been opened for cleaning the original copper patina to bare metal before fitting and soldering.

-

An example of an unrepairable copper standing seam roof.

An example of an unrepairable copper standing seam roof is one with an insufficient pitch or slope. This condition allows for snow and ice accumulation, which can lead to the formation of ice dams during winter. This can cause water to back up and enter the standing seams of the roofing. Furthermore, these roofing joints are caulked instead of properly folded together. The caulking can dry out and crack within a few years due to extreme heat and panel movement.

-

Original installation error.

-

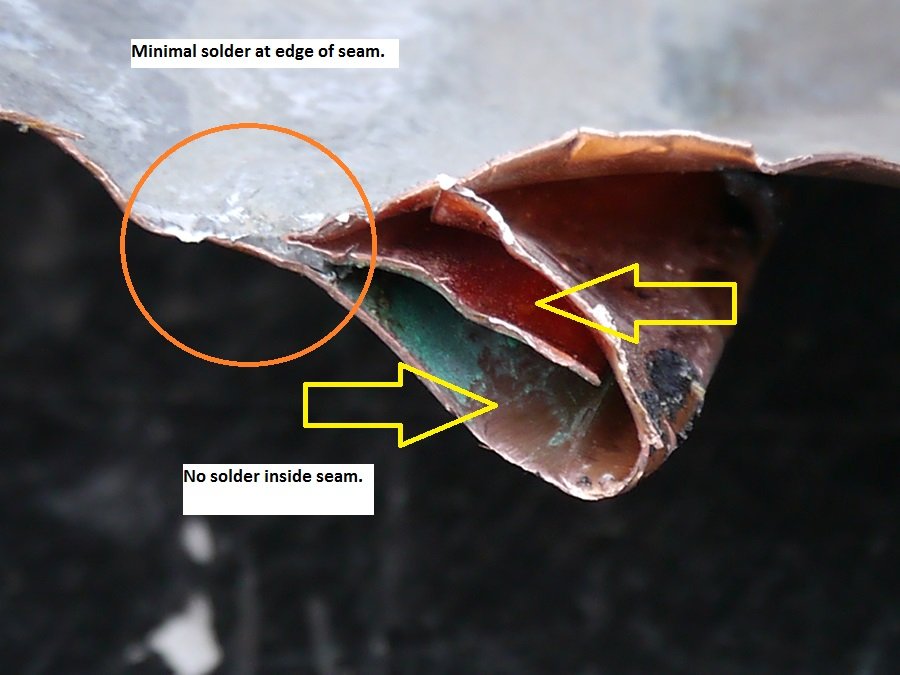

Typical causes of broken seams are incorrect soldering.

Most broken seams look like the image below. There is only a small amount of solder at the seam edge, and no solder is present between the folded layers of copper. These seams are easily broken. If the majority of the roof were soldered in this way, it would be better to replace the entire roof.

And a well-soldered copper roof seam. The solder has flowed through the entire seam for a permanent, unbreakable joint.

-

This copper roof was damaged by a storm and further compromised by both the original and subsequent installation errors.

-

Worn-out copper roofing sheet.

This roof has worn through near the soldered seam. A good indication of worn-out, too-thin-to-solder roofing is the presence of an orange coloring on the copper. The protective copper patina has worn off due to excessive weathering, revealing the bare copper beneath.

Repairing a copper bay window roof in Gates Mills, Ohio.

Our recent repair of a copper standing seam roof in Gates Mills, Ohio.

The copper roof covering the front bay window had been leaking for an extended period, and there had been multiple failed attempts to fix the leaks. We were called in when these attempts were unsuccessful. It became evident that the roof had likely leaked since its original installation.

The standing seam panels, vertical ribs, and panel connections were all carelessly installed, and the prior caulking repairs were inadequate. We were asked to repair the immediate leaking area on the left side of the roof, while leaving the rest untouched to save time and money.

Incorrect installation of roof panels and flashing.

We started by removing two layers of caulking and the wall flashing. The wall flashing had been installed in two pieces of copper, cut to fit the brick courses. The copper was bent over the top of the bricks and secured with steel nails that had begun to rust. Additionally, a cheap acrylic caulk was improperly used as a sealant at the flashing and brick joint.

This method of installing wall flashing will quickly lead to buckling from the sun's heat, causing it to loosen from the caulking. We identified the primary leak at the top of the wall flashing, where it bent around the brick to meet the window. This piece was not cut correctly and was installed below the brick mortar joint.

Beneath this poorly installed flashing lay the main roof panel, which had been cut at the upstand to fit under the window trim—another source of leakage. Around the corner, the wall roof panel was similarly cut and bent against the wall and the lower rib piece. The cuts only had a small dab of caulking applied at the lower corner, which did little to prevent leaking.

Typical standing seam roof leak area

The standing seam panels were installed by bending the edges up three-quarters of an inch, then holding them in place with copper clips. At the intersection with the hip roof, the panel upstands were merely cut and butted together, leaving a large gap—as shown in the picture—where water could easily enter the roof.

The upstand bends were covered with a simple V-bend copper strip, which was secured using an inappropriate punching tool that cut through both the V-cover and the panel upstands.

New copper standing seam panel installed.

We removed all the existing wall flashing and roof panel, then installed new high-temperature underlayment. New gutter board flashing and custom drip edging, extending behind the gutter, were also installed to prevent ice backup into the roof eave. Given the design of this area—the roof being so close to the second-story wall with a gutter and downspout between them—this location is particularly vulnerable to snow buildup and ice damming.

New roof panel and flashing.

A new roof panel was fabricated, along with additional flashing to close the old standing seam hip ridge. These pieces were fitted to cover and protect the existing seams and secured with copper cleats. A groove was cut into the mortar joints of the wall to receive the wall flashing. Individual counter flashing pieces were cut and fitted to the wall, secured with lead and copper nails. A compatible mortar was then mixed, pressed firmly into the joints, and tooled to match the existing masonry.

Copper Roof Leaks in Northeast Ohio | The Usual Suspects

Copper is well-known for its exceptional durability and its ability to withstand prolonged exposure to the elements. When designed and installed correctly, a copper roof can last for centuries with minimal maintenance. However, if it is not designed or installed correctly, the costs of a failing copper roof can far exceed the initial investment. Most failures of copper roofs arise from incorrect installation practices that deviate from established traditional methods. Below, we highlight some of the most common installation mistakes.

-

Incorrect fastening of Copper Sheets

One common issue is the incorrect fastening of the copper sheet at the eave, or edge, of the roof. Often, we see the lower edge of the roofing bent over the gutter board and nailed through the face of the copper. This leads to the nails pulling free due to the expansion and contraction of the copper material. This movement wears on the copper and enlarges the holes made by the nails, allowing water to leak into these expanded holes. As a result, water-damaged roof trim and moldings may occur beneath. If the nails used are steel instead of copper, rust marks can stain the moldings and the paint below.

-

Gaps in the Standing Seam Ribs

Another issue arises from gaps in the seams where the roof panels meet at the eave. If the vertical sections (upstands) are installed too far apart, they allow water to wick back into the roof eave and onto the deck boards. These gaps are typically caused by poor measurement and alignment of the panels, as well as improper closure of the panel ends. Often, the ends of the ribs are butted together and cut straight with no effort made to close them properly. Wicking, or capillary action, is particularly problematic in low-sloped copper standing seam roofs.

-

Incorrect Soldering of Flat Locked Panel Roof Seams

The soldered seams of a flat roof system are crucial for preventing panel buckling and seam cracking. Incorrect soldering techniques, such as using too little or too much heat, soldering too quickly, failing to properly clean the copper, and inadequate flux application, can lead to issues. To ensure a strong joint, the folded seam should be pre-tinned at the edges and thoroughly sweated, applying just enough heat to allow the solder to flow through the joint effectively.

-

Installing Flat Panel Roofing Over Ice and Water Shield

This practice can melt the ice and water shield membrane where the roofing panels are soldered due to the high heat involved in the soldering process. Not only does this compromise the waterproofing membrane, but it also hinders the movement of the roof panels. Additionally, it increases the cost of roof replacement, as the roofing may become stuck together, making removal more time-consuming and difficult.

-

Not Allowing for the Expansion and Contraction of Copper Sheet Metal

Often, copper roofing is nailed directly through the panel into the roof deck. Instead, cleats that allow for movement should be used to secure the roof panels. Additionally, roofing panels that butt up against opposing walls without sufficient room for expansion can create fatigue and cracking of the copper. A small gap, or expansion joint, should be included at obstructions and penetrations during the layout of the roof. One particular area of concern is the drainage holes in parapet walls. These are often made too tight to facilitate easier fabrication and fitting of the drain pipe to the roof connection.

Correct installation of flat seam copper roofing with expansion gap and roof cleats.

-

Installing Standing Seam Roofing on a Low-Pitched Roof

This can be problematic, especially in areas prone to snow and ice buildup or heavy rainfall, where flooding may occur. Standing seams are not waterproof, and standing water can seep into the seams, leading to leaks. Standing seam roofing should not be installed on any roof pitch under 3" per foot.

-

Installing Wall Flashing with Expandable Head Fasteners

Using heavy-duty hammer-in expandable fasteners designed for concrete walls can damage the bricks and stone walls behind roof flashings. Historic buildings are particularly vulnerable, as they often feature softer brick.

-

Fabricating Flat Panels that Are Too Large

Roofing panels larger than 18 x 24 inches are prone to buckling and should be avoided. Large copper sheets can move as much as ¼” along their length due to thermal expansion and contraction, leading to buckling, kinks, failed seams, and fatigue cracks.

-

Butting Panels and Covering with a V-Cap

Correctly formed standing seams involve taking two edges—one longer than the other—from adjoining copper pans and folding them over each other twice. This technique creates a water-resistant seal, allowing for additional folding methods to prevent leaks. Separate cap pieces, also known as V-caps, are fastened using penetrating rivets or screws, and punching tools, which can lead to leaks and problems with joint closure.

-

Using a Gas Plumber's Torch to Solder Roof Seams

Despite being a hazardous practice, some roofers still use open-flame plumbers' torches on roofs, which can result in fire hazards. In addition to the risk of fire, overly hot torches can overheat the solder, causing excessive oxidation and brittleness, which leads to cracked seams.

Numerous issues can be found on the copper roofs of Greater Cleveland, including incorrectly soldered seams, subpar craftsmanship, a lack of traditional metal construction techniques, insufficient expansion joints, and poor design.

At DM Crookshanks Copper Roofing, we are experienced and knowledgeable in the proper design, fabrication, and installation methods to ensure that your copper roof is beautiful, long-lasting, and free from leaks.

If you have a copper roof that is leaking, please call us at 440-285-3200 or contact us .