Common Causes of Copper Roof Leaks in the Greater Cleveland Area

Copper is well-known for its exceptional durability and its ability to withstand prolonged exposure to the elements. When designed and installed correctly, a copper roof can last for centuries with minimal maintenance. However, if it is not designed or installed correctly, the costs of a failing copper roof can far exceed the initial investment. Most failures of copper roofs arise from incorrect installation practices that deviate from established traditional methods. Below, we highlight some of the most common installation mistakes.

-

Incorrect fastening of Copper Sheets

One common issue is the incorrect fastening of the copper sheet at the eave, or edge, of the roof. Often, we see the lower edge of the roofing bent over the gutter board and nailed through the face of the copper. This leads to the nails pulling free due to the expansion and contraction of the copper material. This movement wears on the copper and enlarges the holes made by the nails, allowing water to leak into these expanded holes. As a result, water-damaged roof trim and moldings may occur beneath. If the nails used are steel instead of copper, rust marks can stain the moldings and the paint below.

-

Gaps in the Standing Seam Ribs

Another issue arises from gaps in the seams where the roof panels meet at the eave. If the vertical sections (upstands) are installed too far apart, they allow water to wick back into the roof eave and onto the deck boards. These gaps are typically caused by poor measurement and alignment of the panels, as well as improper closure of the panel ends. Often, the ends of the ribs are butted together and cut straight with no effort made to close them properly. Wicking, or capillary action, is particularly problematic in low-sloped copper standing seam roofs.

-

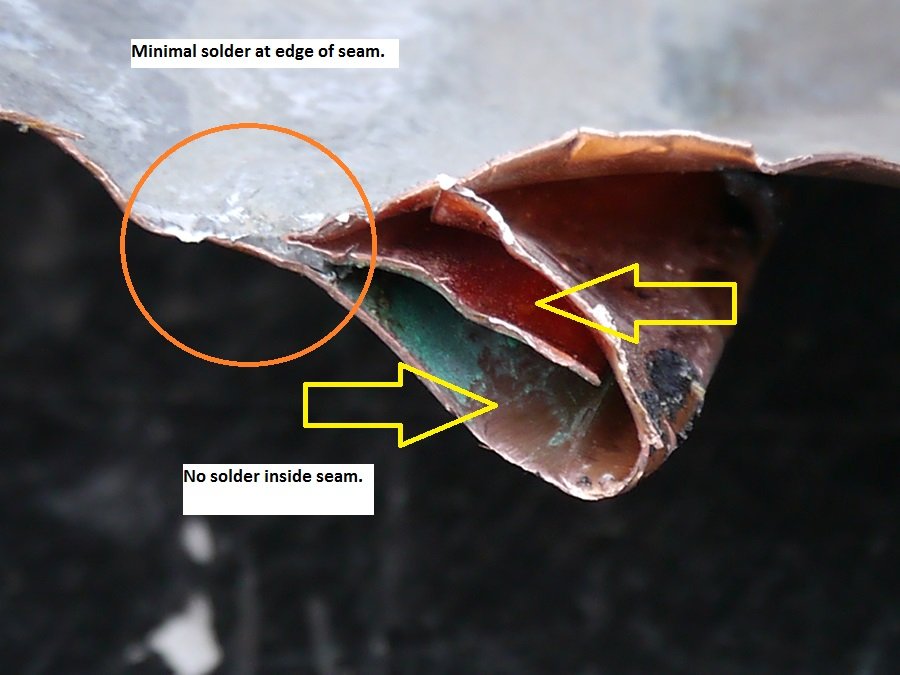

Incorrect Soldering of Flat Locked Panel Roof Seams

The soldered seams of a flat roof system are crucial for preventing panel buckling and seam cracking. Incorrect soldering techniques, such as using too little or too much heat, soldering too quickly, failing to properly clean the copper, and inadequate flux application, can lead to issues. To ensure a strong joint, the folded seam should be pre-tinned at the edges and thoroughly sweated, applying just enough heat to allow the solder to flow through the joint effectively.

-

Installing Flat Panel Roofing Over Ice and Water Shield

This practice can melt the ice and water shield membrane where the roofing panels are soldered due to the high heat involved in the soldering process. Not only does this compromise the waterproofing membrane, but it also hinders the movement of the roof panels. Additionally, it increases the cost of roof replacement, as the roofing may become stuck together, making removal more time-consuming and difficult.

-

Not Allowing for the Expansion and Contraction of Copper Sheet Metal

Often, copper roofing is nailed directly through the panel into the roof deck. Instead, cleats that allow for movement should be used to secure the roof panels. Additionally, roofing panels that butt up against opposing walls without sufficient room for expansion can create fatigue and cracking of the copper. A small gap, or expansion joint, should be included at obstructions and penetrations during the layout of the roof. One particular area of concern is the drainage holes in parapet walls. These are often made too tight to facilitate easier fabrication and fitting of the drain pipe to the roof connection.

-

Installing Standing Seam Roofing on a Low-Pitched Roof

This can be problematic, especially in areas prone to snow and ice buildup or heavy rainfall, where flooding may occur. Standing seams are not waterproof, and standing water can seep into the seams, leading to leaks. Standing seam roofing should not be installed on any roof pitch under 3" per foot.

-

Installing Wall Flashing with Expandable Head Fasteners

Using heavy-duty hammer-in expandable fasteners designed for concrete walls can damage the bricks and stone walls behind roof flashings. Historic buildings are particularly vulnerable, as they often feature softer brick.

-

Fabricating Flat Panels that Are Too Large

Roofing panels larger than 18 x 24 inches are prone to buckling and should be avoided. Large copper sheets can move as much as ¼” along their length due to thermal expansion and contraction, leading to buckling, kinks, failed seams, and fatigue cracks.

-

Butting Panels and Covering with a V-Cap

Correctly formed standing seams involve taking two edges—one longer than the other—from adjoining copper pans and folding them over each other twice. This technique creates a water-resistant seal, allowing for additional folding methods to prevent leaks. Separate cap pieces, also known as V-caps, are fastened using penetrating rivets or screws, and punching tools, which can lead to leaks and problems with joint closure.

-

Using a Gas Plumber's Torch to Solder Roof Seams

Despite being a hazardous practice, some roofers still use open-flame plumbers' torches on roofs, which can result in fire hazards. In addition to the risk of fire, overly hot torches can overheat the solder, causing excessive oxidation and brittleness, which leads to cracked seams.

Numerous issues can be found on the copper roofs of Greater Cleveland, including incorrectly soldered seams, subpar craftsmanship, a lack of traditional metal construction techniques, insufficient expansion joints, and poor design.

At DM Crookshanks Copper Roofing, we are experienced and knowledgeable in the proper design, fabrication, and installation methods to ensure that your copper roof is beautiful, long-lasting, and free from leaks.

If you have a copper roof that is leaking, please call us at 440-285-3200 or contact us .